Making more sustainable decisions

Taking the next step towards sustainability with Siemens EcoTech. Complete transparency about the environmental performance of products sets a new standard for the entire industry.

© Siemens

© Siemens

Taking the next step towards sustainability with Siemens EcoTech. Complete transparency about the environmental performance of products sets a new standard for the entire industry.

With the introduction of its approach to a sustainable product label – Siemens EcoTech – the company is setting a new standard for transparency in the industry. Siemens EcoTech gives customers a comprehensive insight into the sustainability performance of the Siemens portfolio for infrastructure and industrial applications with regard to selected environmental criteria. The Siemens EcoTech label is gradually being extended to relevant Siemens product families that meet the strict criteria.

The introduction of the EcoTech label is a central component of the corporate strategy to promote the circular economy across all sectors and to increase resource efficiency. In fiscal year 2024, the year the label was introduced, more than 25,000 Siemens products received the Siemens EcoTech label because they performed better than the current market standard, predecessor products or applicable standards in three areas – sustainable materials, optimal use as well as value recovery and circular economy. The Siemens EcoTech label represents Siemens’ commitment to providing its customers with the knowledge they need to make informed decisions to support their sustainability goals. Sustainability should be at the heart of every Siemens product.

Siemens uses extensive data provided in the Environmental Product Declaration (EPD) to evaluate the life cycle performance of a product based on a set of sound eco-design criteria. These criteria include various aspects such as the use of low-carbon materials, the use of sustainable packaging, energy efficiency, durability, information on the circular economy and recyclability. These detailed insights form the basis for the Siemens EcoTech Profiles (SEP) – these are product data sheets on the comparable performance of a product in areas such as materials, design, use phase and end of life cycle. This means that Siemens offers more data transparency than any other company in the industry. In addition, all Siemens EcoTech products are manufactured in production facilities that are powered 100 percent by electricity from renewable sources. This contributes to the company’s overall goal of achieving climate neutrality at its production sites and buildings by 2030.

Examples of products that carry the Siemens EcoTech label are:

● The SENTRON ECPD protective switching device: The multifunctional, versatile and compact protective switching device can replace up to ten conventional products with a single device. Compared to conventional solutions, this reduces the amount of material used in production by 1.53 kg (by up to 80 percent for electronics, 90 percent for metals and 90 percent for plastics, depending on the application) and the associated CO2 emissions by 50 percent.

● The Simatic IPC BX-39 industrial PC, which is more than 30 percent more energy efficient than its predecessor.

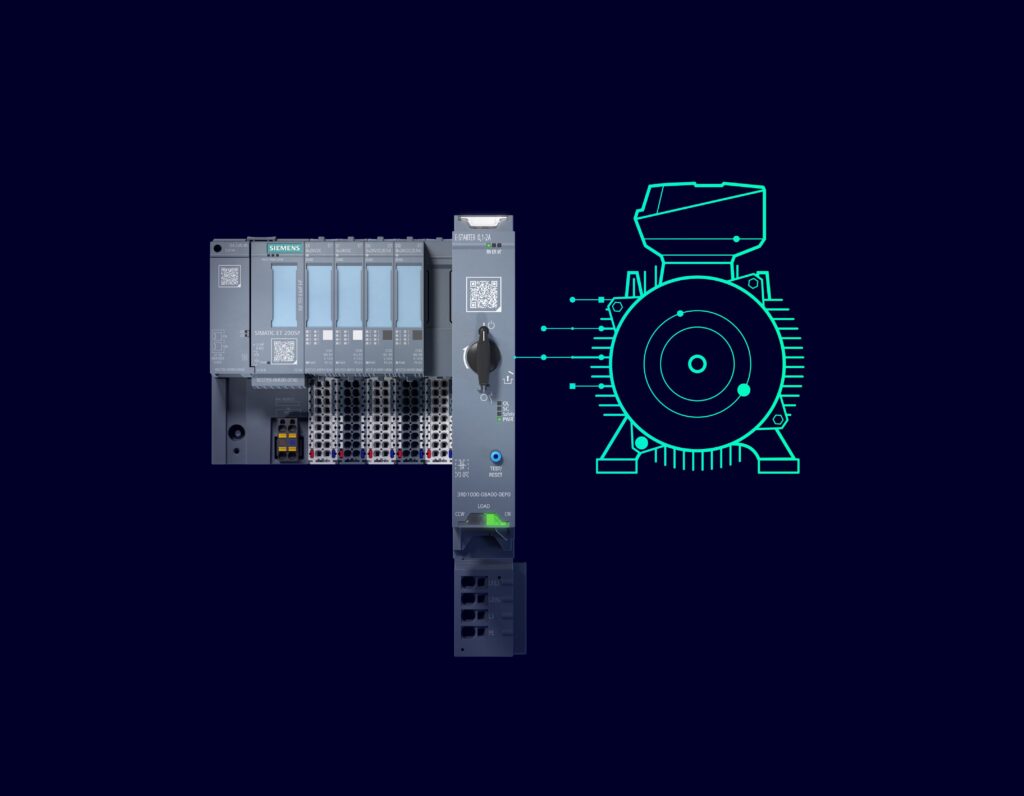

● SIMATIC ET 200SP e-Starter – the first fully electronic starter from Siemens with semiconductor technology. The e-Starter is characterized by short-circuit protection that is a thousand times faster and is virtually wear-free compared to conventional solutions such as circuit breakers or fuses. Minimal use of materials, energy efficiency and durability make the starter a particularly sustainable product. The e-starter not only relies on the use of recycled materials, its lower energy consumption and wear-free switching also offer a longer and more efficient service life.

© Siemens

© SiemensMinimal use of materials, energy efficiency and durability make the SIMATIC ET 200SP e-Starter a particularly sustainable product, which is why it also bears the Siemens EcoTech label.

● SENTRON 5SV3 residual current circuit-breaker, type A/AC – This switch is the first Siemens product to use TECHNYL® 4EARTH® from DOMO Chemicals: a high-performance polyamide made from 50% recycled nylon. The recycled material offers the same performance and quality as conventional materials. In addition to the use of sustainable materials, SENTRON residual current circuit-breakers are designed to exceed the expected service life in accordance with IEC 61008-1. With an impressive 10,000 switching cycles, these devices offer superior mechanical and electronic durability, ensuring reliable performance and longevity.

© Siemens

© SiemensThe SENTRON 5SV3 residual current circuit-breakers, type A/AC, meet the criteria of the Siemens EcoTech label.

Siemens EcoTech is the next milestone in the company’s long-standing commitment to minimizing the environmental footprint of its own operations and products and supporting the digital and sustainable transformation of its customers. Building on the environmental portfolio introduced in 2008, the systematic integration of ecological design principles with the Siemens Robust Eco Design approach from 2020 and the DEGREE framework introduced in 2021 – which offers a 360-degree approach to key sustainability values with clear targets in the four areas of decarbonization & energy efficiency, ethics & governance, resource efficiency & circular economy and equal opportunities & employability – Siemens remains a pioneer in sustainability. More than 90 percent of Siemens’ business today enables Siemens customers to achieve a positive sustainability impact. In addition, the Siemens products and solutions sold in fiscal year 2024 enabled customers to avoid more emissions for the first time than Siemens caused in its entire value chain.

In addition to hi!tech digital, the magazine is also available as a printed edition twice a year.